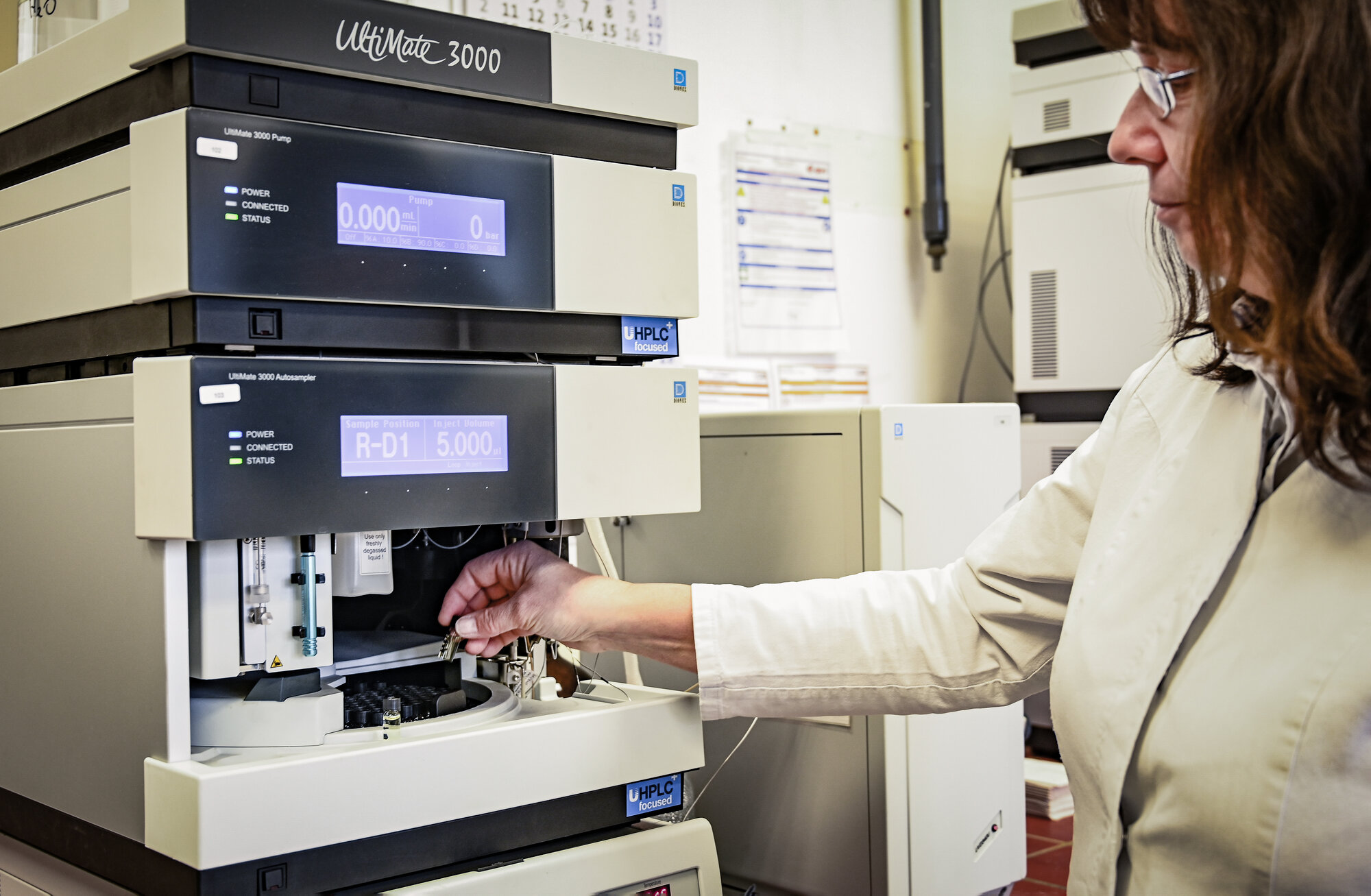

Oil laboratory

more than 30 years of experience

Our laboratory team have more than 30 years of experience in analysing and evaluating lubricating and insulating oils. In addition to analysing oils, we carry out interdisciplinary damage analyses and are also on site at the customer’s premises for sampling, inhibition and assistance with oil changes.

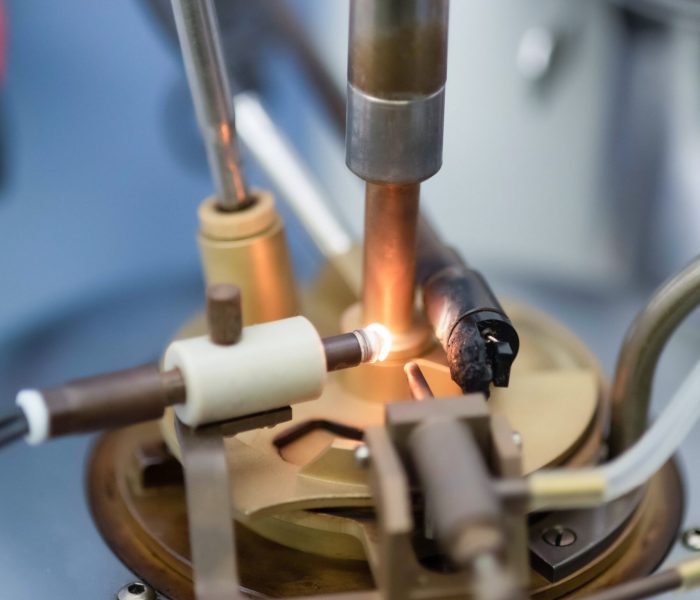

Analysis

Analyses of lubricating oil

Investigation and evaluation of turbine, hydraulic and gear oils.

Analysis

Analyses of insulating oil

Analysis

Analyses of engine oil

Lifetime extension

Inhibitions

Lifetime extensions of oil fillings and chemical cleaning of oil circuits

Quality assurance

Sampling and accompanying of oil changes

Use our know-how on site for quality assurance.

plant failures

early detection

early detection of plant failures

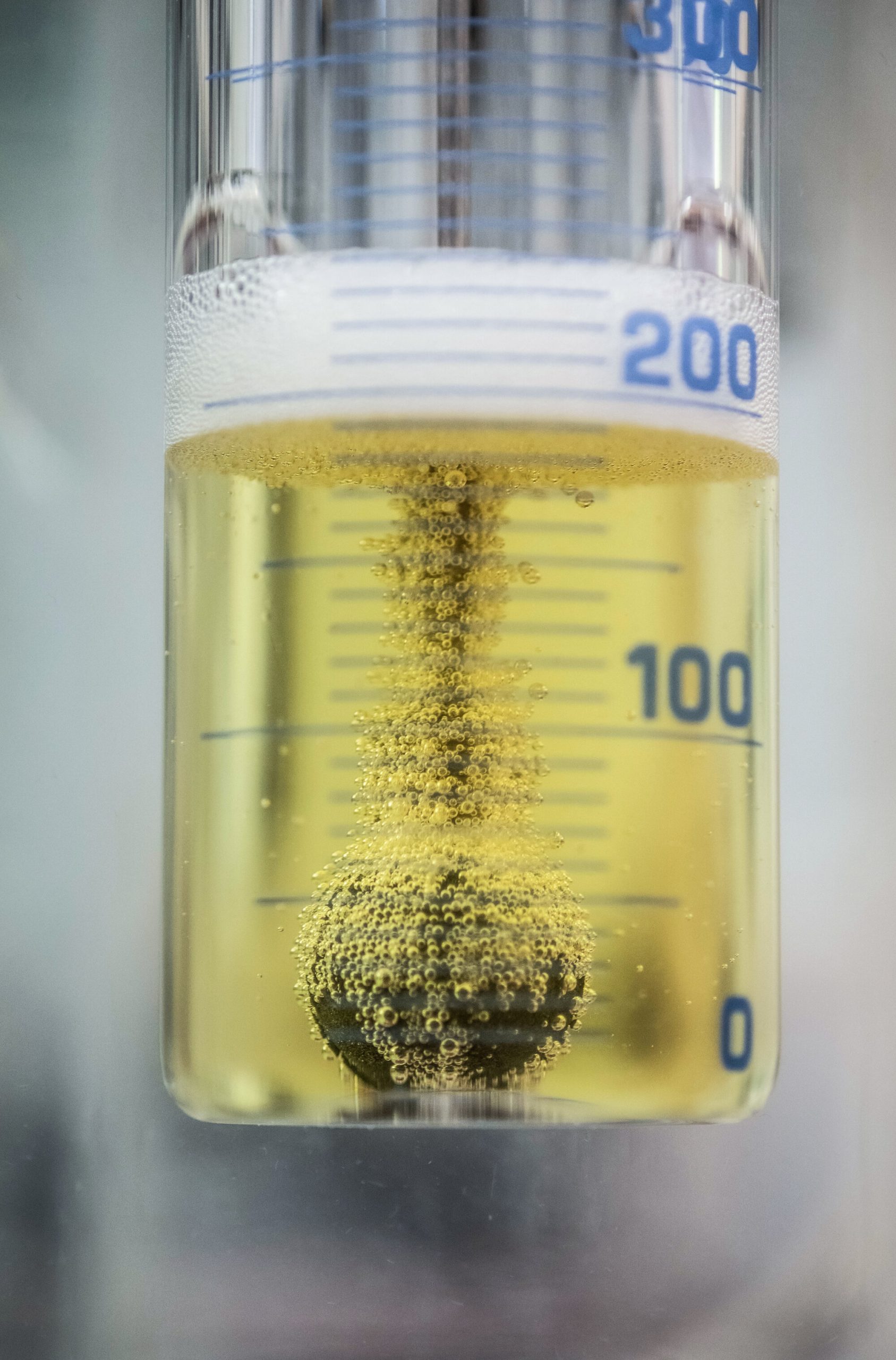

Analyses of lubricating oil

Eine Schmierölanalyse mit der fachkundigen Bewertung ermöglicht das frühzeitige Erkennen von Anlagenstörungen und sich anbahnenden Schäden. Failures and damage are often already recognizable in the oil filling before any effects impair plant operation. At the same time, oil condition analysis and oil development lead to a good lifetime prediction of the oil filling and maintenance measures can be initiated at an early stage for optimum further lifetime.

We analyse lubricating oil in all areas of power generation, but also for a wide variety of other industrial operations. We deal with any oil: from turbine oil of a nuclear or gas power plant, gear oil from a wind power plant or a hydro power plant or compressor oil from a chemical plant.

Energy efficiency through insulation

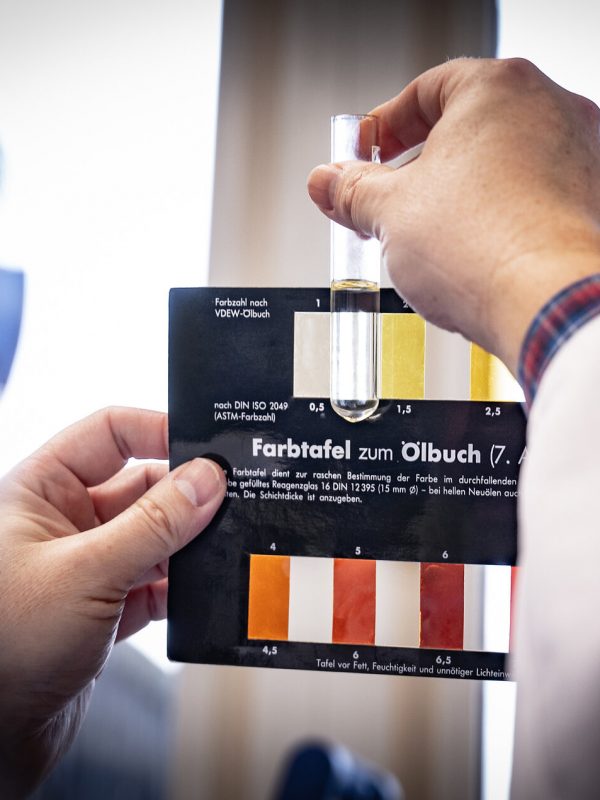

Analyses of insulating oil

Regular condition monitoring is essential for the safe operation of transformers. The current condition of transformers can be easily determined by various examination methods.

By monitoring of harmful gases through gas-in-oil analysis, damage and electrical faults in the transformer can be detected at an early stage and are an important component of condition assessment. Furan analysis is important for detecting and assessing paper decomposition in the transformer.

The insulating oil analysis uses, among others, the safety-relevant parameters of water content and breakdown voltage to examine the operational capability of the insulating oil filling.

Optimise maintenance intervals

Analyses of engine oil

Gas engines are important for the energy transition. Apart from the input fuel itself, engine oil and its lifetime are important factors for plant operation and operating costs. Regular engine oil analysis ensures high availability and optimises oil change intervals.

As suggests by name, emergency power diesels must be instantly available in an emergency/exceptional situation. Thus, regular monitoring of diesel engine oil quality is an absolute necessity to meet the high demands on availability of emergency power diesels.

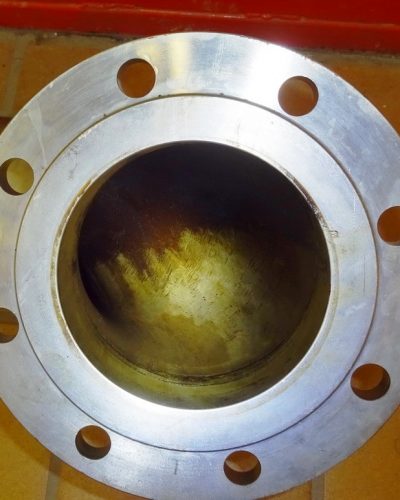

Lifetime extensions of oil fillings

Inhibitions

Oil fillings reach the end of their lifetime due to the degradation of additives, although the oil properties are still sufficient for further operation. Therefore, the VGB Oil Laboratory developed methods to refresh specifically degraded additives. In this process, additives, such as ageing protection, are added in a concentration adapted to the oil type during plant operation.

With this technique, we regularly refresh oils in very different oil systems.

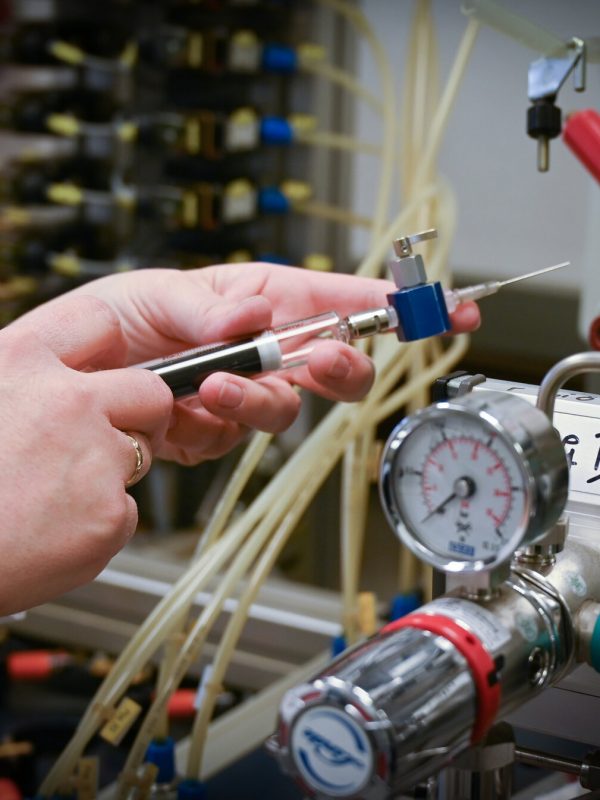

Benefit from our know-how on your plant site

On site

Quality assurance and extending the lifetime of machines

Sampling and accompanying of oil changes

Correct sampling is the prerequisite for meaningful oil analysis. In addition to training, we also take samples of lubricating and insulating oils. This is done with a high degree of professionally and in compliance with the highest standards of environmental protection and occupational safety.

Only the correct selection of oil guarantees long and trouble-free use of a new oil filling. Particularly in case of large or critical oil systems, which cannot be changed quickly, it is worth taking a special look at quality assurance. We offer accompanying quality management, which includes, for example, ensuring the oil quality guaranteed by manufacturer, tank acceptance tests and monitoring of flushing.

Advanced training

Experts

stay up-to-date

Success with advanced training

Advanced training

Training and advanced training of employees is important for overall successful operation. We offer training courses on topics such as sampling and oil management which are bespoke to your needs and which can be conduct on your premises. You will find information on current events and dates on the vgbe website under “Events” or in the vgbe Newsletter.

Essential part

Consultancy & Service

In addition to oil examination, consultancy is an essential part of our service.

Proper maintenance measures, selection of the right type of oil, blendability of oils or reduction of oil types at site are, for example, frequent questions arising in daily routine.