Quality assurance and inspection

The vgbe team quality assurance and inspection is controlling quality within the scope of new built projects, partial renewal and inspections in order to improve plant safety and availability for the benefit of operators.

The scope of activities covers relevant power plant components such as:

- Gas and steam turbine

- Generator

- Boiler components

- Piping systems

We support you

Quality assurance

Quality assurance is achieved in manufacturing and assembly through:

- Control of approvals, certificates and verifications

- Monitoring of ongoing production and assembly

- Inspection of welding work

- Checking of rubber linings and coatings as well as corrosion protection work to be carried out

- Participation in or, if necessary, performance of non-destructive tests and checking of their results

- Final inspection of finished components and review of documentation

Supervision of assembly and comissioning worldwide

Our experience

Our international reputation

is competence and reliability

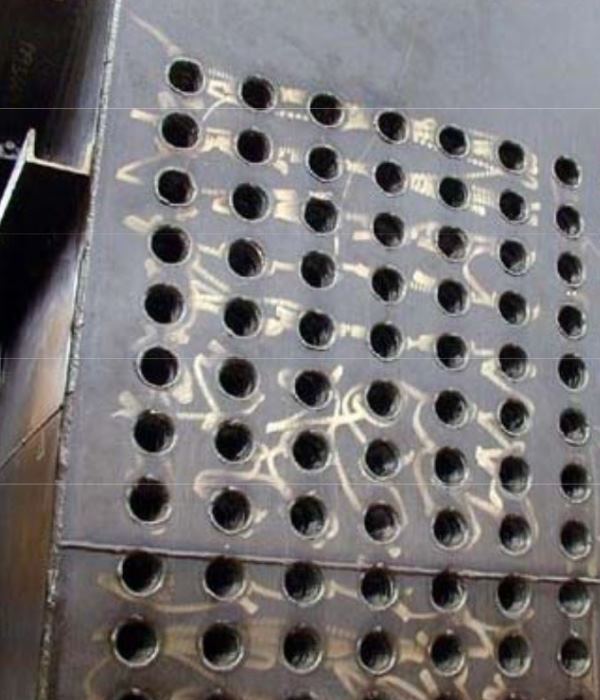

Checking of an LP turbine casing half

Weld seam for joining two tube sheets is located at the vertex of the tube weld-in seams