Materials Laboratory

more than 40 years of experience

Experience for over 40 years in the field of damage analysis and condition monitoring of power plant components as well as practice-oriented research and development work in the field of materials engineering.

Damage analysis

with

lifetime monitoring

In particular

Advanced training

Workshops

Our team

Our team

Systematic damage analysis

Quickly identify the cause of damage

damage analysis

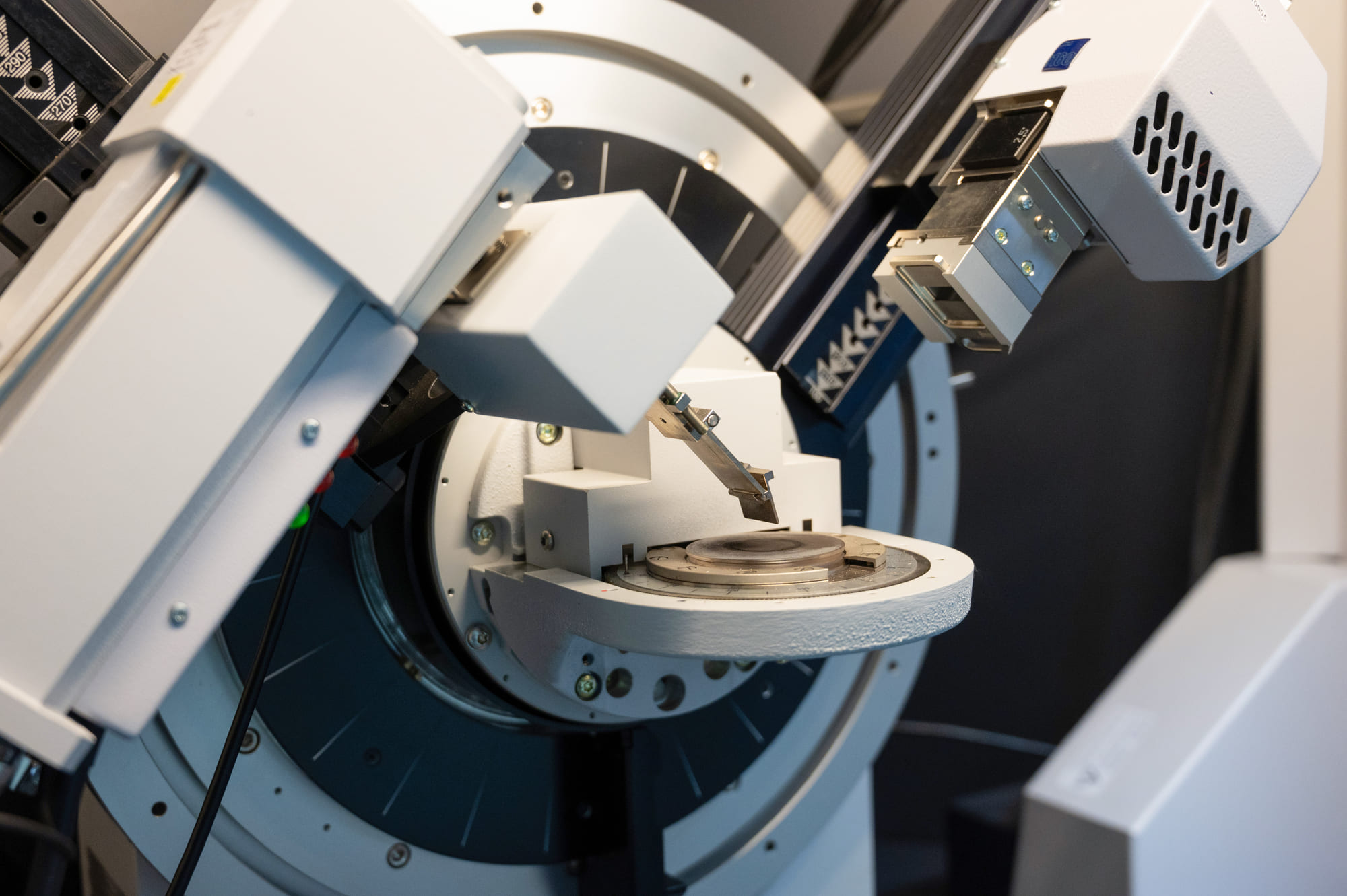

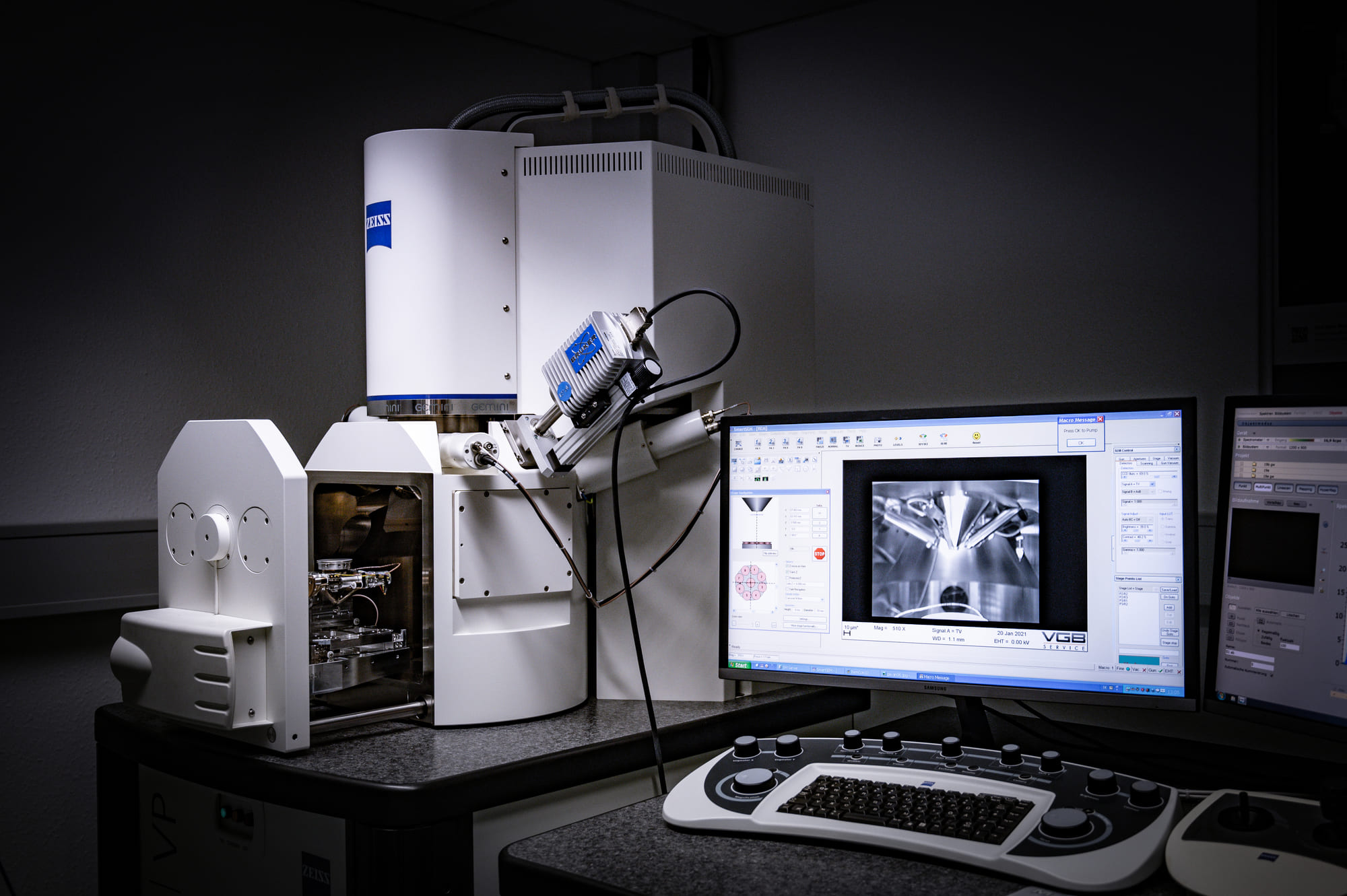

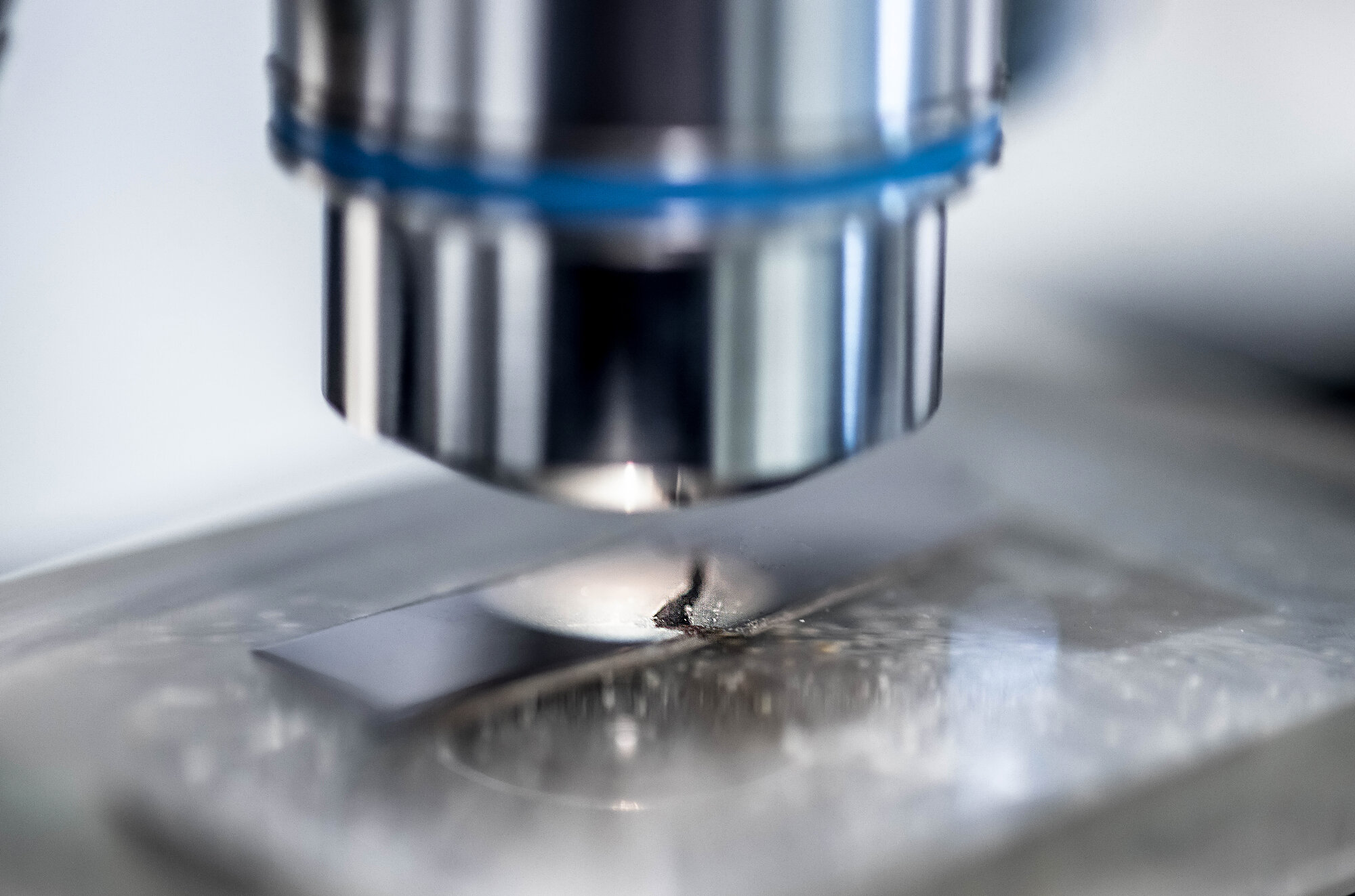

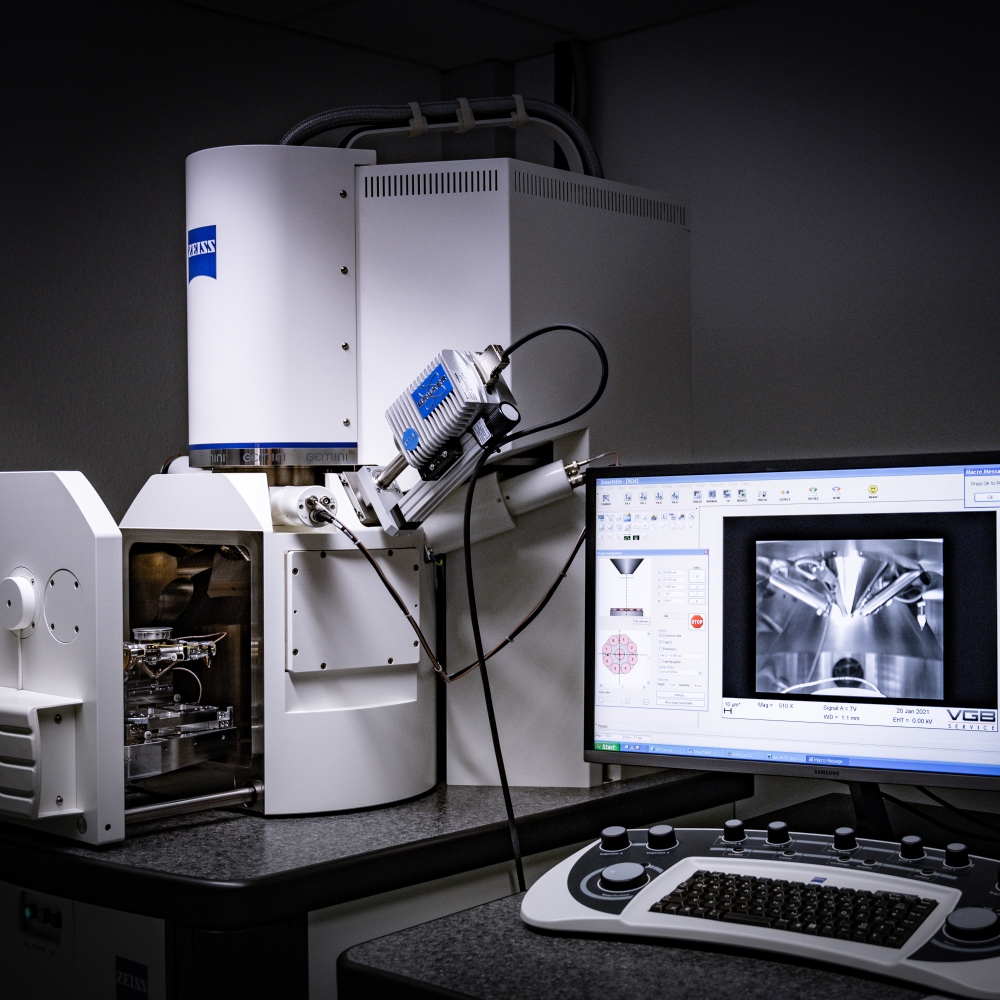

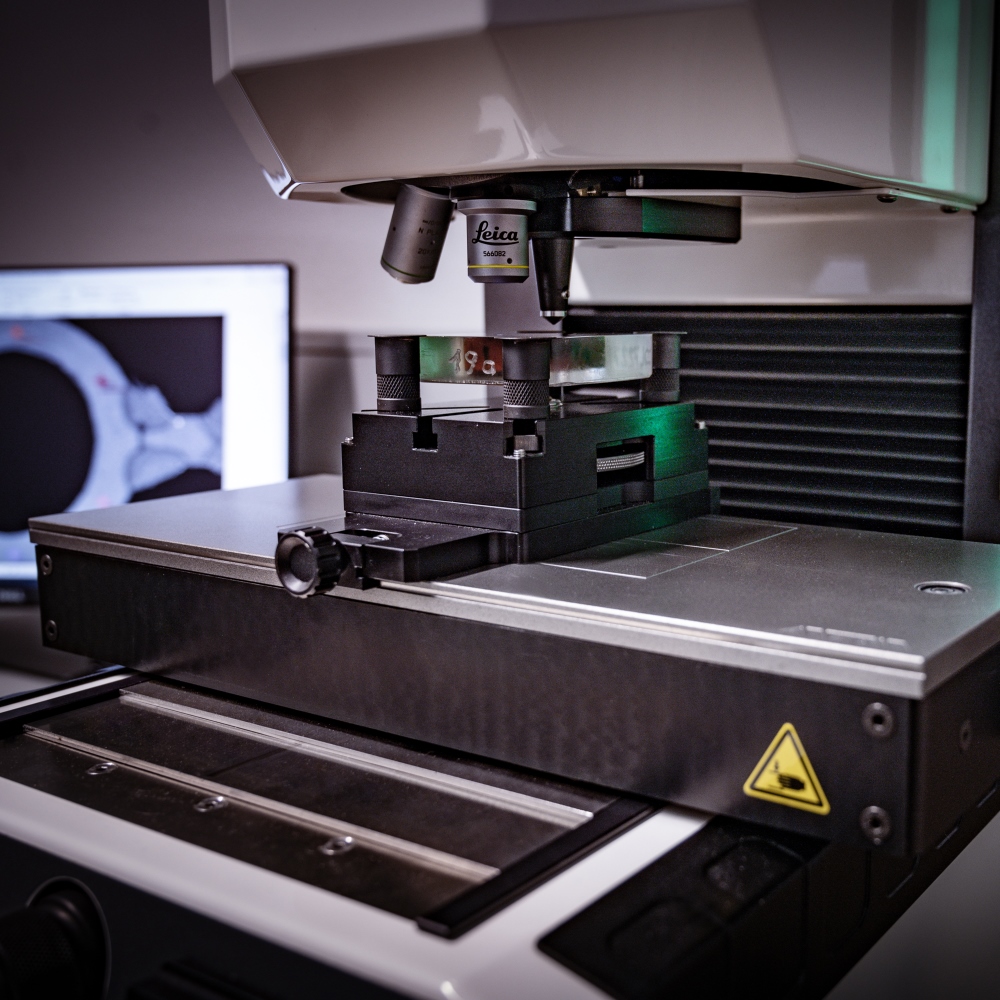

Damage analysis is always aiming at identifying the cause of damage or the underlying mechanism. For this purpose, your damaged component is examined by our experienced experts using state-of-the-art analytical methods. We are constantly expanding our testing and examination technology to keep up with latest testing developments. Currently, these include a field emission scanning electron microscope (FE-SEM), an X-ray diffraction system and a fully automatic hardness tester. With this equipment, we can identify damage features and characteristics that would otherwise not be revealed. The team expand their knowledge through the constant exchange of experience with other experts, also from other disciplines.

One step ahead

lifetime monitoring

The materials laboratory of vgbe energy service GmbH has a broad portfolio for reliably assessing the service life of your plants. In particular, we take into account VGB Standards, such as VGB-S-509 “Contents of recurring tests on pipelines and their components in thermal power plants”.

We basically apply three concepts to monitor lifetime of plant components.

Using calculations analogous to the design calculation, system parts are recalculated with their real geometric dimensions recorded by us. In this way, the service life consumption can be calculated theoretically.

The application of on-site measurements, such as creep strain transducers or additional temperature measurements, can provide valuable information about stress and lifetime of the system. The creep strain measurement, which we apply in particular to weld seams and pipe bends, has often enabled us to predict the service life more precisely and thus continue to operate components with creep damage in a controlled manner. This enables safe and at the same time economical operation of the plants.

Every operator knows the difference between theory and practice. For recording real lifetime consumption of your component, practical in-service inspections in the plant on site are still imperative. These periodic tests include, among other things, examination and evaluation of the microstructure by replica testing. In addition to evaluation of creep stress, this method often allows statements to be made about heat treatment condition of the material, especially in conjunction with mobile hardness testing.

Replica testing is always carried out strictly in line with the specifications of the VGB Standard VGB-S-517 “Guidelines for rating the microstructural composition and creep rupture damage of creep-resistant steel for high-pressure pipelines and boiler components and their weld connections”. This is important to exclude misinterpretations and to obtain a reliable statement about the condition of the component. In addition to replica tests, the inspection for internal flaws by means of ultrasonic inspection is becoming more and more important due to the more flexible operation of many plants. VGB is using both a conventional ultrasonic as well as a new phased-array testing device for such examinations.

Advanced training

Experts

stay up-to-date

Success with advanced training

Avanced training & Workshops

We offer the workshop “Damage in Power Plants” at regular intervals. In this workshop, the experience gained from damage analysis is passed on in a very practical manner. For us it is important to enable plant operators on site to recognize damage mechanisms and to learn suitable strategies to avoid such damage. The face-to-face event is supplemented by a live online version. You will find the latest information on the vgbe website under “Events” or in the vgbe Newsletter.